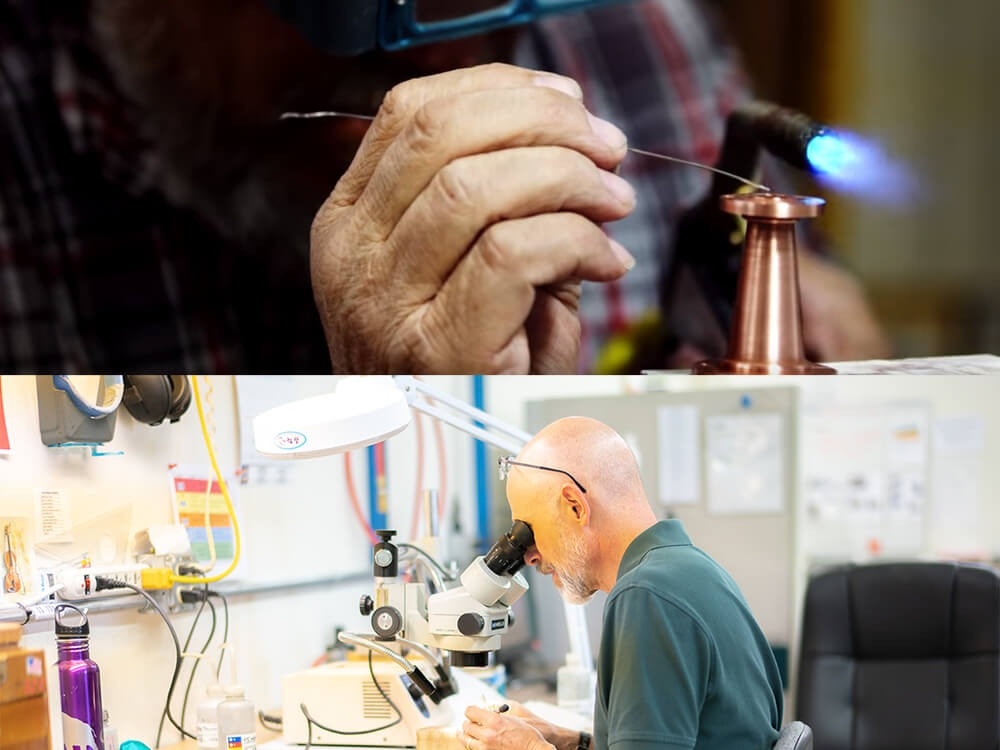

Design. Manufacture. Test.

Custom Microwave Inc. is a proven provider of high-performance, passive antennas engineered, manufactured, and tested for space and ground applications. We have a history of successfully designing and delivering size-competitive solutions to meet any signal requirements. Reach out to discuss how we can simplify your system integration process.

Contact Us55+

Years Experience

230+

Satellites with CMI Hardware

54,000 SQ FT

Facility