Assembly, Integration & Test

Custom Microwave Inc. has many years of experience with the final stage of flight hardware production: Assembly, Integration, and Test (AI&T). We understand what it takes to plan for and succeed with the production of highly complex and intricate assemblies involved in achieving high performance and high volume antenna feeds and components.

With our extensive library of test components and long heritage of performing challenging RF and environmental tests on our passive microwave hardware, our team of skilled test technicians and engineers are used to performing under tight timelines to fulfill our obligations to our customers.

CONSIDER MOVING TO CAPABILITIES PAGE

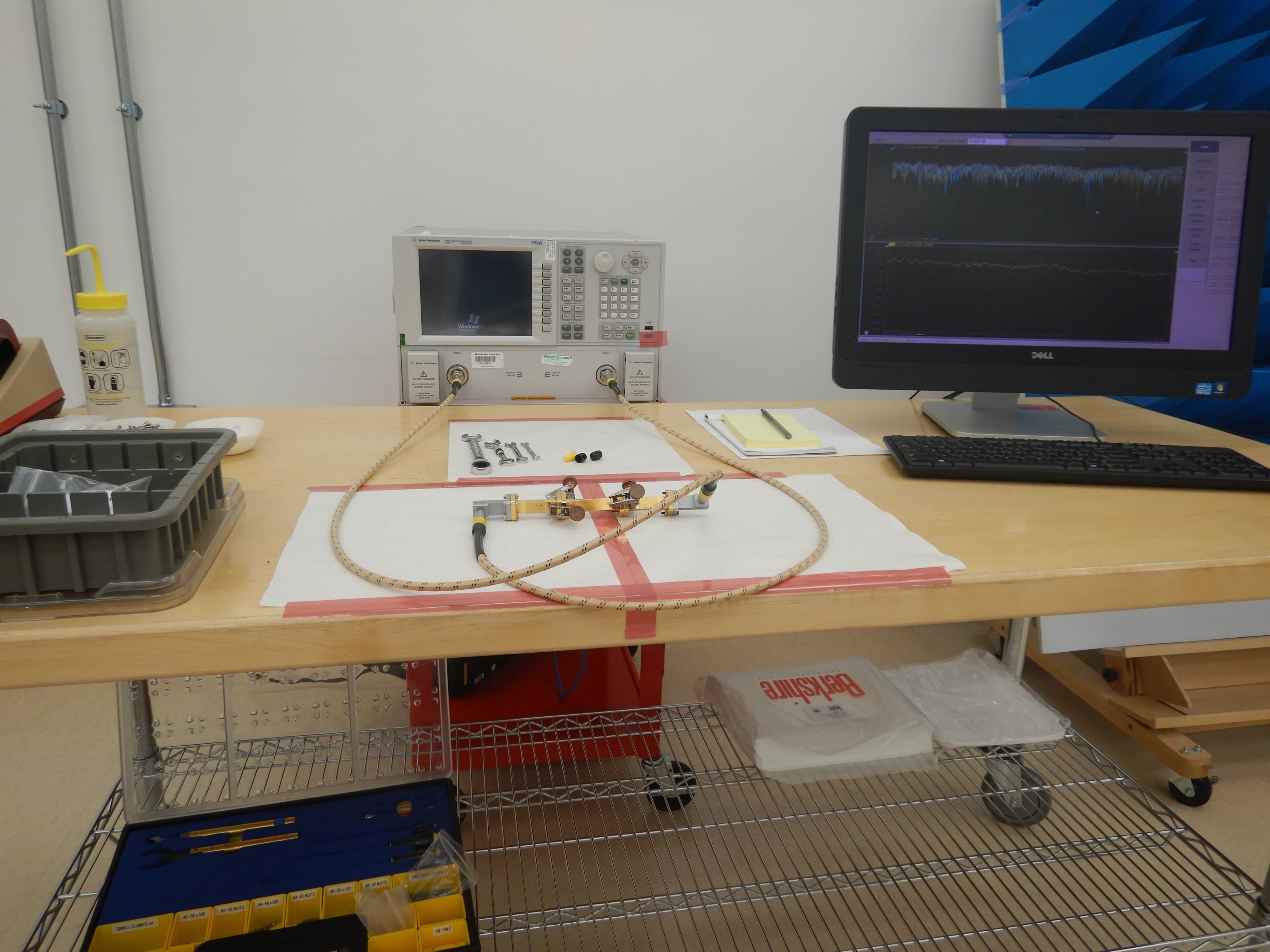

RF Bench

CMi Maintains a clean room environment in which to perform precision assembly and RF Bench testing of passive microwave components. We have high performance network analyzers and precision calibration kits covering DC - 110 GHz, with experience testing up to 220 GHz. We routinely measure typical low insertion losses and high isolations, and also more challenging balanced amplitude and phase parameters of OMTs, Polarizers, Hybrids, and BFNs.

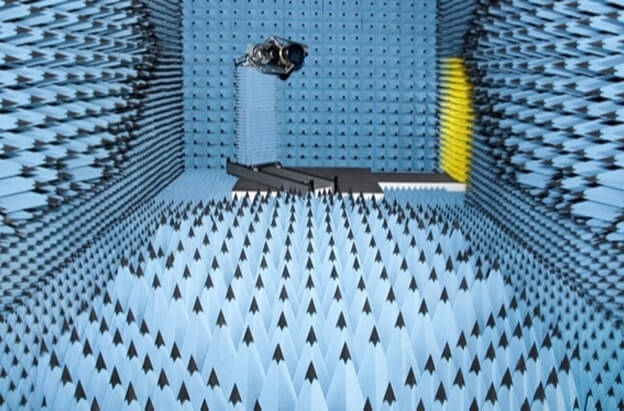

Far Field Range

CMi has tested hundreds of spaceflight antenna feeds in our 30’ X 14’ X 14’ symmetric far field range. We have extensive experience measuring low cross polarization, low axial ratio, and other challenging linear and circular polarized pattern parameters. Our range is configurable from 1-40 GHz, split into typical waveguide banded source horns and standard gain horns.

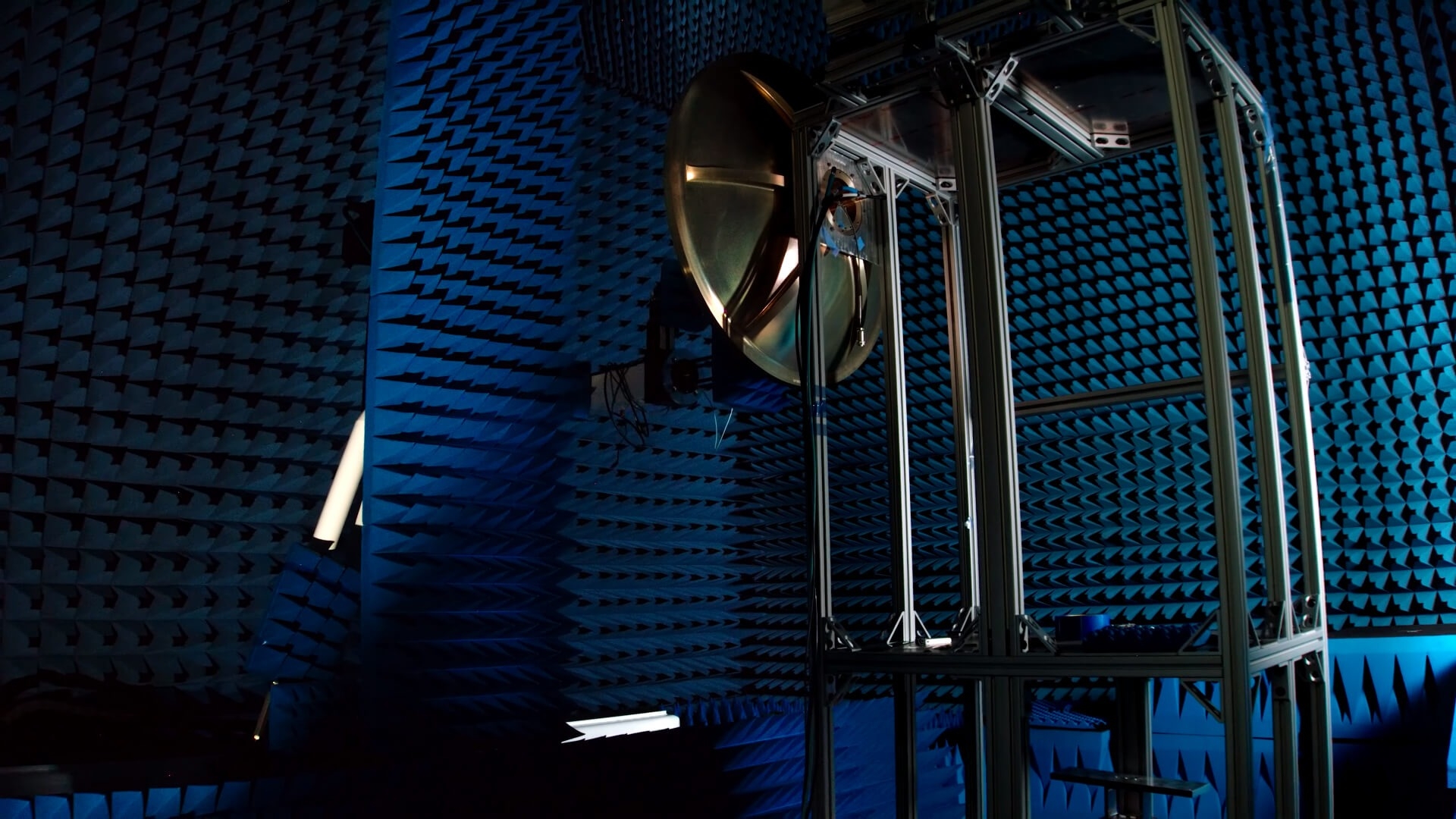

Near Field Range

CMi’s NSI~MI 8X8 Planar Near Field Range is able to maintain a planarity of 0.001” across the full scan range, for highly accurate pattern measurements up to 110 GHz and beyond. The same range has been configured at various lower frequency bands, including L-, Ku-, K-, Ka-, Q-, and V-Bands. Along with precise gain and radiation pattern measurements, we have heritage with holography, low axial ratio measurements, and more.

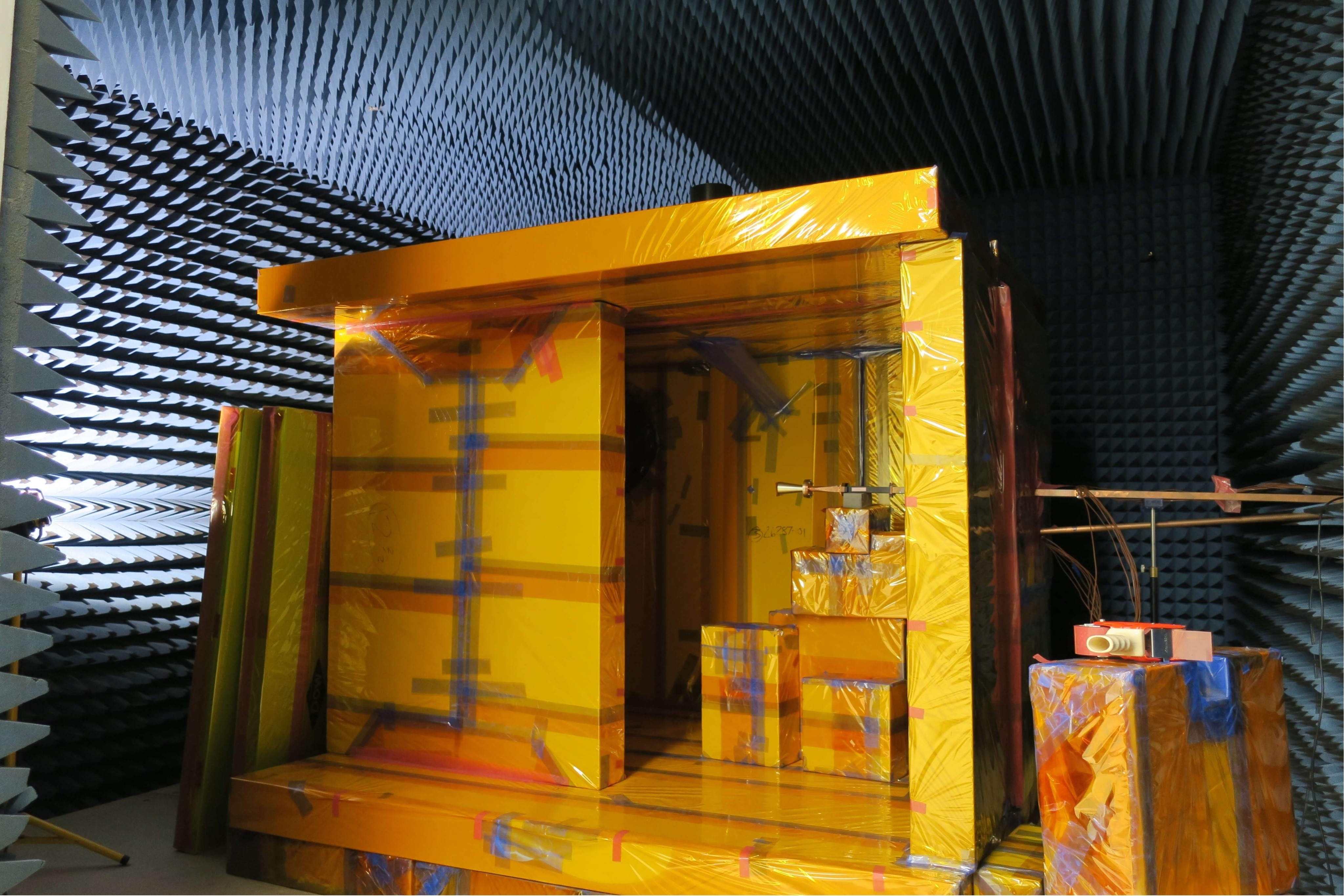

Passive Intermodulation

Ullamcorper a lacus vestibulum sed arcu non. Lectus mauris ultrices eros in cursus. Vivamus at augue eget arcu dictum. Sagittis aliquam malesuada bibendum arcu vitae elementum. Vehicula ipsum a arcu cursus vitae.

Thermal Cycle

Ullamcorper a lacus vestibulum sed arcu non. Lectus mauris ultrices eros in cursus. Vivamus at augue eget arcu dictum. Sagittis aliquam malesuada bibendum arcu vitae elementum. Vehicula ipsum a arcu cursus vitae.

Thermal Vacuum

Ullamcorper a lacus vestibulum sed arcu non. Lectus mauris ultrices eros in cursus. Vivamus at augue eget arcu dictum. Sagittis aliquam malesuada bibendum arcu vitae elementum. Vehicula ipsum a arcu cursus vitae.

Environmental Testing

We have the capability to test how our parts or yours will hold up under the harsh conditions imposed by space flight.

Vibration Lab

We are equipped to provide full space qualification vibration testing using our Unholtz-Dickie T-2000 series shaker system.

We have completed over 350 tests on feeds and components in our facility.

Our system supports up to 20,000 lbf with vertical and horizontal axis support.

Do the dimensions matter here? Why does the 40 Channel M+P International DAQ matter? How does it compare to other controllers?